Effect of Micromeritics Property on Preformulation: Particle Size, Particle Shape & Density

1. Particle

Size:

·

Characterized

using these term:

o

Very

coarse (#8)

o

Coarse

(#20)

o

Moderately

coarse (#40)

o

Fine

(#60)

o

Very

fine (#80)

·

Size of

the particles may be expressed as follows:

o

Surface

diameter, ds

o

Volume

diameter, dv

o

Projected

diameter, dp

o

Stokes

diameter, dst

o

Sieve

diameter, dsieve

o

Volume

– surface diameter, dvs – same volume to surface area ratio

|

Table 1.1: Common Techniques

for Measuring Fine Particles of Various Sizes

|

|

|

Technique

|

Particle size

(micro meters)

|

|

Microscopic

|

1-100

|

|

Sieve

|

>50

|

|

Sedimentation

|

>1

|

|

Elutriation

|

1-50

|

|

Centrifugal

|

<50

|

|

Light scattering

|

0.5 - 50

|

Methods to determine particle size:

·

Sieving:

o

Simple

& inexpensive

o

Dry

powder require

·

Microscopy:

o

Particle

size determine by calibrated grid background

o

Calibration

factore:

o

(No. of

division of stage micrometer/No. of division of eye-piece micrometer)*100

o

Slow and

tedious method

·

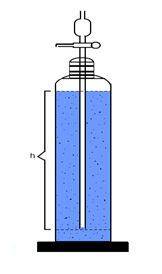

Sedimentation

method:

o

Particle

size calculated by stokes law

o

o

Where,

§

h =

distance fall in time, t

§

no =

viscosity of medium

§

ps =

density of particles

§

po =

density of dispersion medium

§

g =

gravitational acceleration

§

t =

time

·

Light

scattering:

o

Particle

size determine by the diversion of light pathway that reaching the sensor.

o

Quick

and fast

Particle size effect on following:

·

Formulation:

o

Uniform

particle size and shape have good flow properties

o

Uniform

size particle produce good & uniform dispersion

o

Uniform

size produce good compaction during tablet manufacturing

§

Defects

in tablets have less chances

o

Size

alsoplays a role in the homogeneity of the final tablet.

o

Large

differences in size exist between the active components and excipients, de-mixing

effects can occur.

·

Bioavailability

o

Uniform

and smaller size particles have good absorption and therefore good

bioavailability.

o

For

example, the bioavailability ofgriseofulvin and phenacetin is directly related

tothe particle size distributions of these drug

o

It is

now generally recognized that poorly soluble drugs showing a dissolution rate-

limiting step in the absorption process will be more readily bioavailable

when administered in a finely subdivided

state than as a coarse material

·

Stability:

o

Smaller

particle (in colloidal range) improve stability of dispersion

o

Bcz,

§

Brownian

motion observed

§

Therefore

sedimentation is law

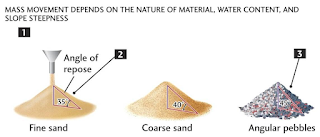

2. Particle

Shape:

·

Formulation:

o

Sphere

particle have good flow property compare to other

o

Irregular

shape particle have not good flow property because they cloge during movement

o

Packing

and compaction property depend on particle shape

o

Parenteral

formulation have only sphere particles

·

Bioavailability:

o

Surface

area à Dissolution à absorption

o

Surface

area also depend on shape of particle

o

Increase

surface area à increase bioavailability

·

Stability:

o

Sphere

particle take more time to stable compare to other shape of particle

3.

Density:

The ratio of mass to volume is known as density

·

Types of density:

o

Bulk

density:

§ Bulk drug

powder is sieved through 40 mesh screen. Weight is taken and poured into a

graduated cylinder via a large funnel. The volume is called bulk volume.

o

Tapped

density:

§

Bulk

powder is sieved through 40 mesh screen.

§

Weight

is taken and poured into a graduated cylinder.

§

The

cylinder is tapped 1000 times on a mechanical tapper apparatus.

§

The

volume reached a minimum – called tapped volume.

o

True

density: It actual density of the solid material.

§

Solvents

of varying densities are selected in which the powder sample is insoluble.

§

Small

quantity of surfactant may be mixed with the solvent mixture to enhance wetting

and pore penetration.

§

After

vigorous agitation, the samples left to stand undisturbed until floatation or

settling has reached equilibrium.

§

The density of that solvent is determined

accurately with a pycnometer.

o

Granule

density:

§

may

affect compressibility, tablet porosity, disintegration, dissolution

·

Source of variation of bulk density:

o

Method

of crystallization, milling, formulation.

Significance:

·

Bulk

density:

o

Bulk

density is required during the selection of capsule size for a high dose drug.

o

In case

of low dose drug mixing with excipients is a problem if the bulk densities of

the drug and excipients have large difference.

·

Tapped

density:

o

Knowing

the dose and tapped density of the formulation, the capsule size can be

determined.

·

True

density:

o

From

bulk density and true density of powder,

the void volume or porosity can be measured.

Comments

Post a Comment